The Joint Team from Boreas Cryogenics and SITP Achieves Significant Progress in the Theoretical Research and Experimental Verification of the Heat Switch Characteristics for the mK Dilution Refrigerator

Back

2024-03-06

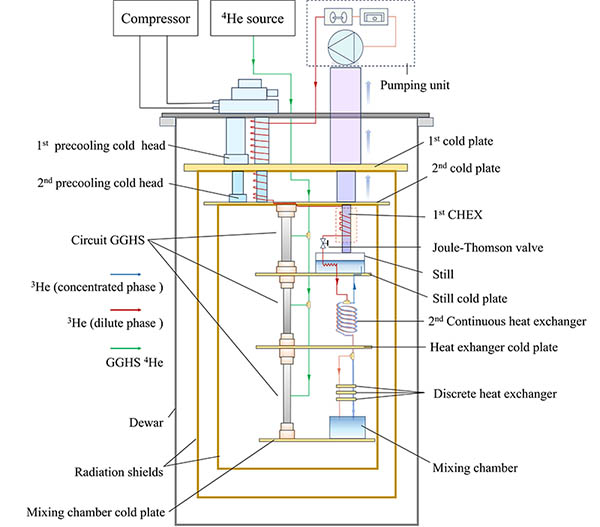

The dilution refrigerator is a relatively complex system that requires the cooperation between the key components with different functions to achieve its stable operation in the mK temperature range. The cooling process from ambient to mK temperature involves several critical phases: pre-cooling, deep cryogenic, and extremely-low temperature range.

However, the requirements of these different cooling stages for refrigeration and heat transfer are contradictory, thereby making the dilution refrigerator system subtle and complex.

For example, during the intital cooling phase, all the cold stages are at ambient temperature. The cooling power of the pre-cooling stage must be rapidly transferred to the lower and extremely-low temperature stages. This requires extremely-low thermal resistance to enable efficient cooling power transfer.

However, in order to reach the thermal equilibrium, normally at around 4 K, the two stages with lower temperature need to be cooled to the sub-Kelvin temperature range. At this time, the pre-cooling stage becomes a heat load. Apart from the internal-circulating components, it requires complete physically isolation from the subsequent stages to enable further cooling into the sub-Kelvin range. Therefore, we need a component whose thermal resistance of the refrigeration system is as small as possible when there is a certain specific need, but becomes infinitely large when there is another specific need. In the subsequent practice, scientists invented such a component - the heat switch.

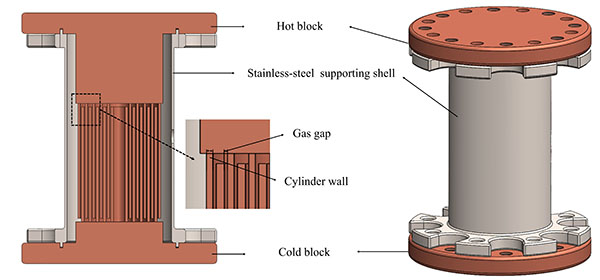

There are many types of heat switches, but few can be used in dilution refrigerators. A novel circuit gas gap heat switch (GGHS) has been developed by the joint team. It has rotationally symmetric structure with annular fin arrangements strengthening the heat-transferring effect.

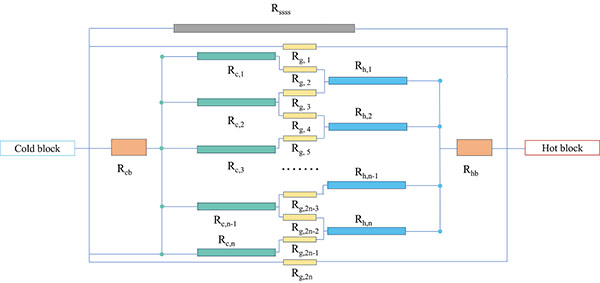

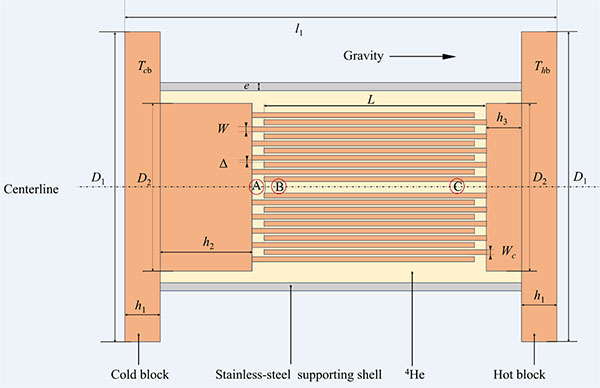

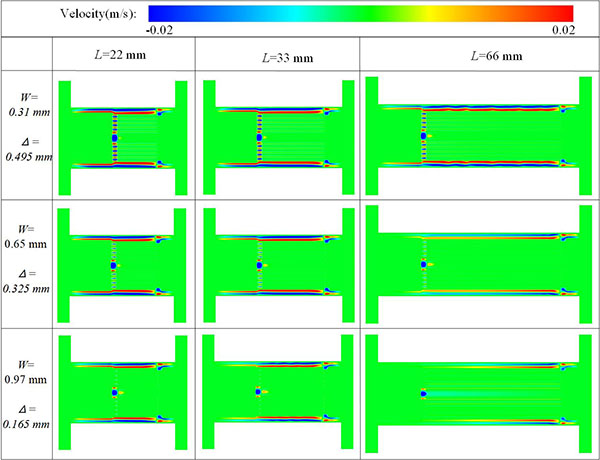

The team proposed a numerical simulation model considering the actual gas properties of helium in wide temperature ranges to investigate the heat transfer and flow characteristics in the circuit GGHS, in which the effects of charge pressure, cold end temperature, thickness and length of walls on the mean thermal conductance (MTC) are studied.

Combined with the dilution refrigerator prototype, the rationality of the simulation model is validated. The research results published in the journal Cryogenics.

Fig. 1. Schematic of the cryogen-free dilution refrigerator with the circuit GGHS.

Fig. 2. The geometry of the developed circuit GGHS.

Fig. 3. Diagram of thermal resistance network.

Fig. 4. Schematic of the circuit GGHS used in the CFD simulation

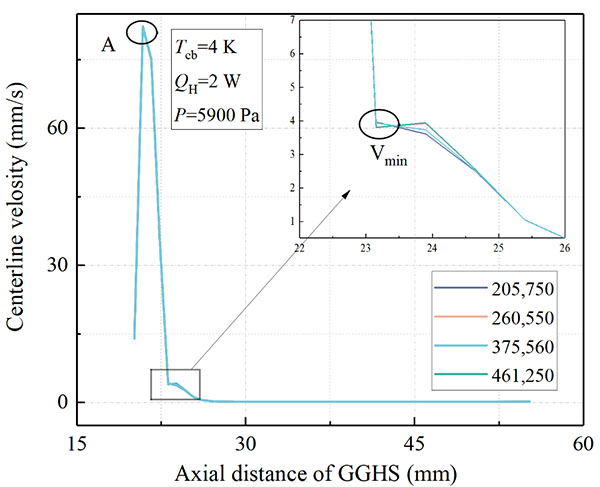

Fig. 5. Centerline velocity of the circuit GGHS.

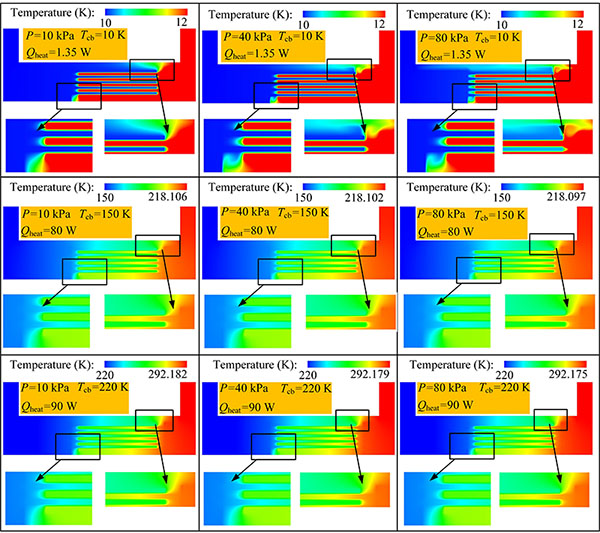

Fig. 6. Contours of temperatures when the charge pressure and Tcb vary.

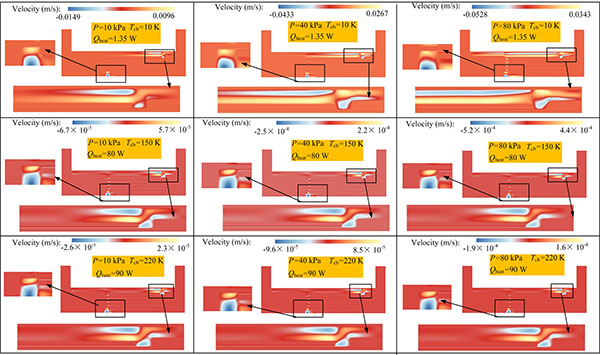

Fig. 7. Contours of velocity when the charge pressure and Tcb vary.

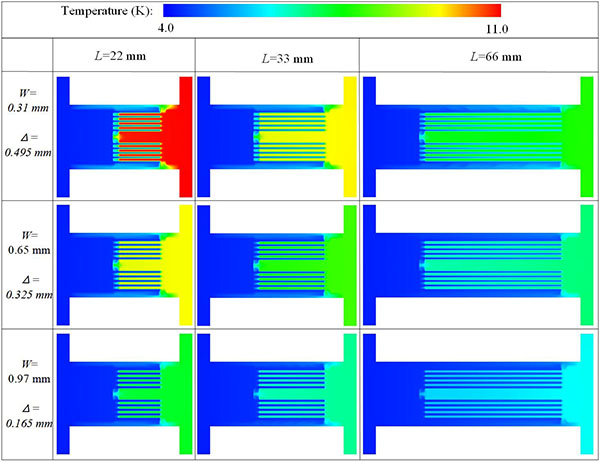

Fig. 8. Contours of the temperature for various geometric parameters.

Fig. 9. Contours of velocity for various geometric parameters.

Fig. 10. Experimental results with various charge pressures; Pc and P are charge. pressure at room temperature and the pressure at 10 K. L and W are cylindrical wall length and hot end wall thickness of the GGHS in experiment, respectively and Tcb is the cold block temperature for the given heating power.

The above research results not only provide theoretical guidance for the design and optimization of heat switch for dilution refrigerators, but also support the productization of mK cryogen-free dilution refrigerators through the development of key componements.

Link to the article:

Back